Company:Lanteky mechatronics

Address:No 5558 Chuansha Road, Pudong Discrict, Shanghai, China

Postcode:100102

Email:landy.industry20@gmail.com

QDY15 Series Servo Valve

DescriptionQDY15 series double nozzle flapper servo valve is a key control part of the electro-hydraulic servo control system, acting on electro-hydraulic conversion and power amplification. It consists of electro-mechanical conversion, power amplifier, feedback.

Advantages

1. This servo valve has great performance on fast dynamic response, pressure sensitivity and linearity, small zero drift, low required input. power.

2. Force feedback servo valve adopts stainless steel shell, with the characters of compact structure, light weight.

3. It is allowed to select the 5th oil port for controlling the pilot valve separately.

4. Our self-developed servo valves have been widely used in metallurgy, aerospace, shipbuilding, automobile, textile and printing industry.

Component of Double Nozzle Flapper Servo Valve

Electro-hydraulic servo valve is a closed-loop control system, which generally consists of electro-mechanical conversion, power amplifier, feedback.

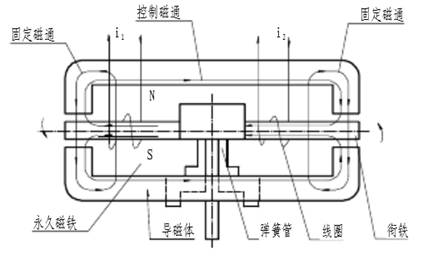

1. Electro-mechanical conversion parts: in nozzle flapper servo valve, electro-mechanical conversion parts is a torque motor, the principle of operation is to convert the current of input coil swinging into the mechanical energy of the armature.

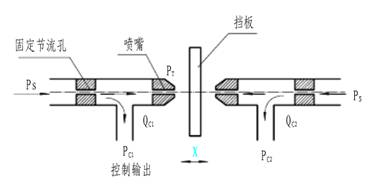

2. Power amplifier section: power amplifier is convert the input mechanical energy of the swing armature into the hydraulic energy of pressure and flow. In QDY series electrical feedback valve, the power amplifier is mostly achieved by flapper-structure.

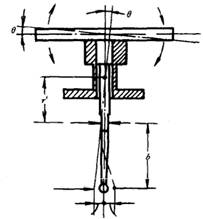

3. Feedback: this part is to feedback the output pressure or flow to the preceding stage as the displacement, force or other forms. Due to this feedback mechanism, the servo valve itself is a closed-loop control system. QDY series servo valve is force feedback servo valve, to achieve the feedback function by bezel components.

Parameters of Double Nozzle Flapper Servo Valve

|

Type |

|

QDY15 |

|

|

Supply

oil pressure range |

Mpa |

1.5 to 25 |

|

|

Rated

supply oil pressure |

Mpa |

21 |

|

|

Rated

flow QN [L/min] (at valve pressure drop of

7MPa) |

L/min |

4, 10, 20,

40 |

|

|

Rated

current In |

mA |

30, 40 |

|

|

Hysteresis |

% |

≤3 |

|

|

Resolution |

% |

≤0.5 |

|

|

Non

linearity |

% |

≤±10 |

|

|

Asymmetry |

% |

≤±10 |

|

|

Pressure

gain |

% |

>30 |

|

|

Internal

leakage |

L/min |

≤1.5 |

|

|

Bias |

% |

≤±3 |

|

|

Zero

drift of supply oil pressure(80 to 110% Ps) |

% |

≤±2 |

|

|

Zero

drift of return oil pressure(0 to 20% Ps) |

% |

≤±2 |

|

|

Zero

drift in temperature(-30 to +150) |

% |

≤±4 |

|

|

Frequency |

Amplitude

frequency width (-3db) |

Hz |

>50 |

|

Phase

frequency width (-90°) |

Hz |

>60 |

|

|

Work

temperature |

℃ |

-40 to +100 |

|

|

Net

weight |

Kg |

0.8 |

|

Related Products

QDY15 Series Servo Valve

QDY15 Series Servo Valve

QDY10 Series Servo Valve

QDY10 Series Servo Valve

AG40 CNC EDM Blade Grinder

AG40 CNC EDM Blade Grinder

DLQ6/32 Grease Injection Valve

DLQ6/32 Grease Injection Valve

DLQ10/50 Grease Injection Valve

DLQ10/50 Grease Injection Valve