Company:Lanteky mechatronics

Address:No 5558 Chuansha Road, Pudong Discrict, Shanghai, China

Postcode:100102

Email:landy.industry20@gmail.com

Home » Products » Electric Discharge Machine (EDM) » CNC EDM Blade Grinder » AG40 CNC EDM Blade Grinder

AG40 CNC EDM Blade Grinder

DescriptionAG40 CNC EDM grinding machine is mainly used for manufacturing and grinding PCD cutters in wood processing industry (Like composite floor and bamboo floor), Aluminium, printed circuit board, nonmetal material cutters and other PCD cutters.

Structure Characteristics of CNC Cutter Grinder

1. The mainframe uses C-type pedestal with cross feeds units structure.

2. The work piece dividing spindle adopts high precision harmonic reduction drive.

3. The high precision touch trigger probe is used to measure the cutters.

4. High precision variable speed electrode of R axis can auto-adapt electrode to turning cut and grinding cut.

5. Light sensation protection and temperature sensitive fire extinguisher ensure safety.

Technical Features of CNC Cutter Grinder

1. Configuring high efficiency and high finish-degree power for processing PCD. The wave of discharging is auto-adjusted during processing. Cutting efficiency is high and the quality of PCD cutter’s edge is excellent.

2. The special software of the cutters can process automatically as the parameters you set. Reduce the manual operation and can ensure good consitency.

3. Tooth pitch of disc-type cutter can be measured automatically, automatic indexing, self-compensation and automatic processing.

Parameters of CNC EDM Grinding Machine

1. Disc-type cutter

| Diameter | 400mm, 630mm |

| Aperture of the cutting bar | MIN 10mm |

| Blade | 14mm |

| Relief angle | 45° |

| Tooth crown angle | 60° |

| Altitude difference of the cutter tooth | allowed |

2. Electrode

| Diameter of electrode | 120mm |

| Diameter of mounting hole of electrode | 30mm |

| Height of electrode | 40mm |

| Rotation rate of discharging processing | 700rpm |

| Rotation rate of discharging processing | 1000rpm |

| Displacement of oil pump | 30L/min |

| Volume of oil pump | About 100L |

| Total input power | 3kW |

| Power source | 380V/3 phase/50Hz |

| Overall dimensions | 2246 × 1860 × 2360 mm |

| Weight | 2500Kg |

3. Control system

There are advanced multi-axis motion controller and servo motor drive.

NC-axes: 4 axes

X axis — cutter grinding feed, electrode turning

Y axis — swing grinding, electrode turning

Z axis — swing grinding, probe measuring

B axis — cutter index location, relief angle

Manual shafts: 3 axes

Tooth crown angle C1, tool cutting edge inclination A and electrode swing angle C2

Related Products

GW735P CNC EDM Machine

GW735P CNC EDM Machine

SVA-Ⅱ Servo Amplifier

SVA-Ⅱ Servo Amplifier

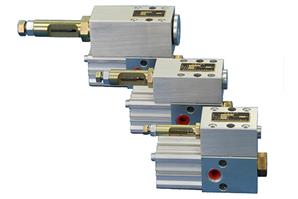

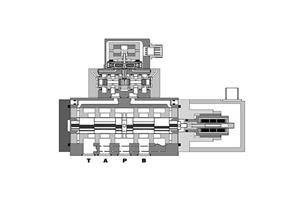

QDY18 Series Servo Valve

QDY18 Series Servo Valve

DLQ6/14 Grease Injection Valve

DLQ6/14 Grease Injection Valve

QDY3 Series Servo Valve

QDY3 Series Servo Valve