Company:Lanteky mechatronics

Address:No 5558 Chuansha Road, Pudong Discrict, Shanghai, China

Postcode:100102

Email:landy.industry20@gmail.com

Home » Products » Electric Discharge Machine (EDM) » Single Axis CNC EDM Machine » FN2P CNC EDM Machine

FN2P CNC EDM Machine

DescriptionFN2P CNC EDM machinery is suitable for machining small-middle size of dies and other parts. The electrical cabinet is integrated with the host, small footprint, which is easy to mount.

Single axis CNC EDM machine is a machining device that to eroding the material in a certain liquid medium based on the electric erosion phenomena of the pulse discharge working on the conductor. To make the work piece meet the technical requirements of its shape, size and the surface finish quality after machining.

Products Component

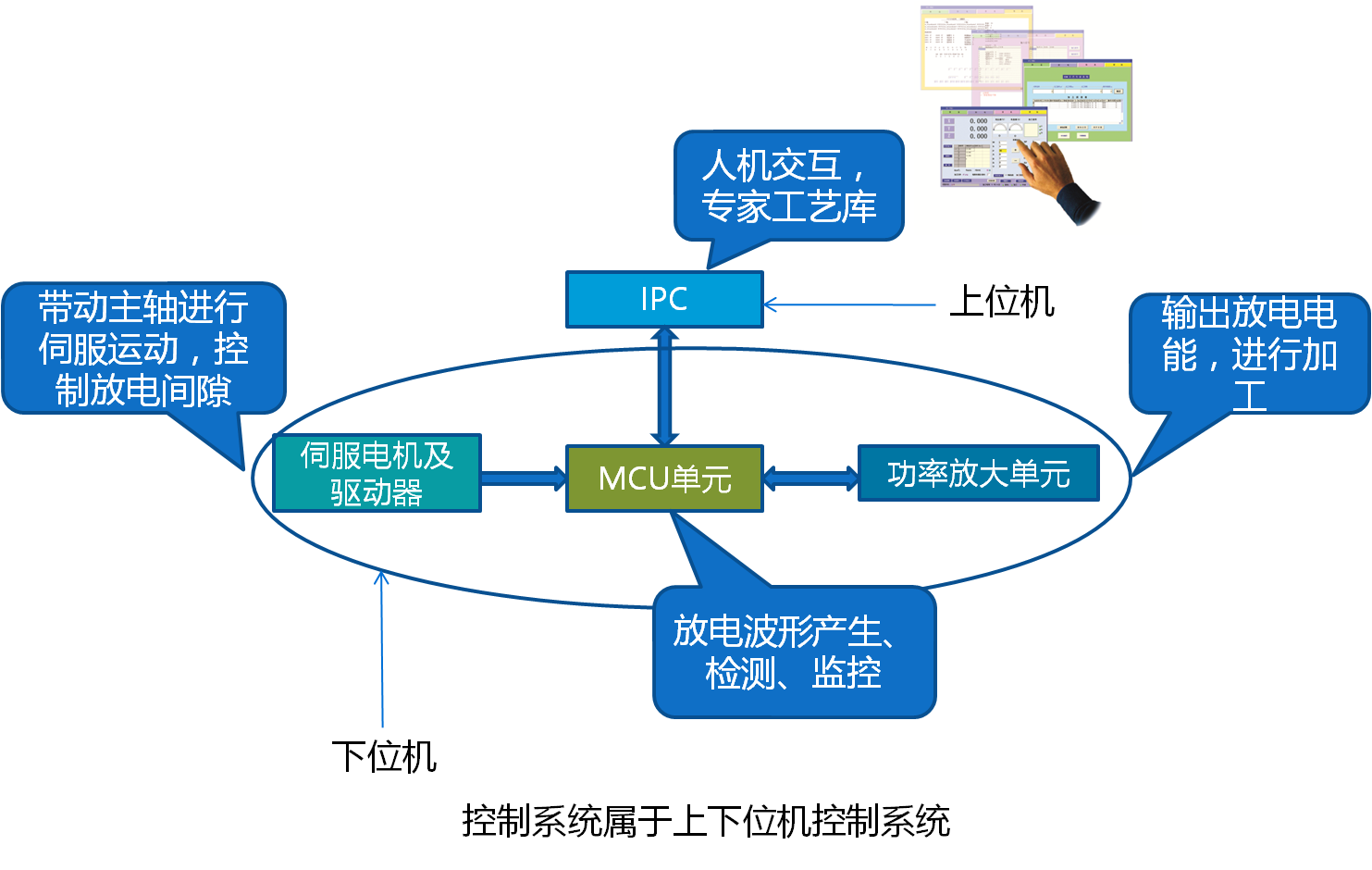

The electrical discharging power is divided into host computer and lower pulse control system.Machining tool consists mechanical bed, pulse power, control system, etc.

1. Host computer is the core of the whole system, which is responsible for running the exporter system and monitoring the whole system. This part is based on the new type of embedded industrial process control computer (IPC), which is stable and reliable. And can be upgraded following the advancing of the electronic industry.

2. Power pulse control system is in charge of generating and adapting the pulse energy, which takes Adaptive Control Algorithm to assure the purity of electrical pulse. This part is composed with micro-controller, programmable logic devices, power devices and other devic

Structure of the whole system includes

1. IPC (human-computer interaction, expert process database)

2. Servo motor and driver(drive the spindle do servo motion, control the discharge gap)

3. MCU unit (generate, detect and monitor the wave of electrical pulse)

4. power amplifier (output the electric energy for processing).

Advantages of EDM Machinery

1. The system has rich expert technology database and processing strategies.

2. Real time display of processing parameters and status.

3. The expert processing system can generate entire processing parameters from rough to finishing machining according the user’s preference to machining accuracy or speed.

4. Discharge sensitivity setting: The adaptive control algorithm can implement adaptive adjustment to the discharge state, to reduce the abnormal discharge and improve the quality of processing.

5. The system can handle multistage complex processing. The finishing condition of processing can be set as timing machining or machining as a given depth.

Characteristic of EDM Machinery

1. Simple and friendly system interface helps to operate more accessibility.

2. Oriented programming based on the expert system is easy to handle, Keeping the user free of professional knowledge.

3. Real-time status display, intelligently monitoring the discharging progress according user’s setting.

4. Using isopulse power supply technology, the single axis NC EDM machine can control every discharge pulse power precisely, with advanced spark monitoring system.

5. Control and detection every discharge spark, processing fine machining and complex structure parts.

6. Energy-saving and environment-friendly goals are achieved by replacing current-limiting resistance with power inductor, meet the trend of green technology.

7. Standard module design is convenient for energy-expanding.

8. Unique pulse character has outstanding performance on processing cemented carbide.

Parameters of EDM Machinery

|

|

|

FN2P |

|

|

Machine

tool |

Machine

weight |

Kg |

1500 |

|

Overall dimension |

mm |

1320 × 1630

× 2120 |

|

|

Stroke |

X axis |

mm |

300 |

|

Y axis |

mm |

250 |

|

|

Z axis |

mm |

250 |

|

|

Distance

between tip of spindle and table surface |

mm |

250 to 500 |

|

|

Work

range |

Worktable

dimension |

mm |

500 × 300 |

|

Oil

tank dimension |

mm |

800 × 520

× 375 |

|

|

Maximum

weight of electrode |

Kg |

50 |

|

|

Maximum

weight of work piece |

Kg |

300 |

|

|

Oil box |

Capacity |

L |

400 |

|

Filter |

|

2 paper

filter element |

|

|

Pulse power

supply |

Type |

|

Isopulse power

supply |

|

Peak

current(standard configuration) |

A |

32 |

|

|

The

best surface roughness(Ra) |

μm |

0.4/0.15 |

|

|

Minimum

electrode wear |

|

0.1% |

|

|

Maximum

machining efficiency 32A (64A) |

mm³/min |

180(400) |

|

|

96A(128A) |

mm³/min |

600(800) |

|

|

|

|

|

|

|

External

power grid |

Three-phase

input voltage |

V |

380 |

|

|

Consumed

power 32A, 64A, 96A, 128A |

KVA |

3,5,7,10 |

|

Optional

accessories |

Add 32A, 64A, 96A, 128A pulse power supply, Super fine module, Low loss module |

|

|

|

Dielectric

fluid cooling device |

|

|

|

|

Micro

fine pulse power supply |

|

|

|

|

Translational

head(NC/manual operation) |

|

|

|

Related Products

DLQ6/32 Grease Injection Valve

DLQ6/32 Grease Injection Valve

QDY62 Servo Valve

QDY62 Servo Valve

QDYB6 Proportional Valve

QDYB6 Proportional Valve

QDY6 Series Servo Valve

QDY6 Series Servo Valve

DLQ10/80 Grease Injection Valve

DLQ10/80 Grease Injection Valve