- Electric Discharge Machine (EDM)Electrical discharge machine works by using the erosion caused by the impulse discharge between the electrode and the conductive material, which has b...

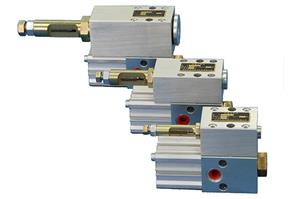

- AmplifierThe amplifier is the servo drive for driving and controlling servo valves and proportional valves. It can realize high accuracy control of all kinds o...

- Electro-hydraulic Servo ValveElectro hydraulic servo valve can measure the hydraulic oil according to input signal, then to control position, speed, pressure or force in the elect...

- Electro-hydraulic Proportional ValveElectro hydraulic proportional valve is a hydraulic component, which can translate electrical signal to displacement signal by an analog electric-mach...

- Grease Injection ValveGrease injection valve is an equipment that can output high pressure medium quantitatively. It is the most important part of the quantitative filling ...

- Single Axis CNC EDM MachineSingle axis CNC EDM machine uses a single axis (Z-axis) with auto-feeding control system (including servo feed system and parameters control system), ...

- Three Axis CNC EDM MachineWith auto-feeding control system (including servo feed system and parameters control system), three axis CNC EDM machine has wonderful performance on ...

- CNC EDM Blade GrinderCNC EDM grinder is a machine that can produce PCD cutters through grinding. With 4 CNC controlled axes and 2 manual axes, which is used for the comple...

- CNC Wire Cut EDMOur CNC wire cut EDM machine is mainly used to process high-precision moulds and work pieces. And as a medium-speed...

- General Purpose Wire Cut EDMThis general purpose wire cut EDM can satisfy various work piece processing requirements in different fields. And its main components are mainly ...

- Wire Cut Control SystemThis wire cut control system, also called wire cut controller, is mainly used for programming, controlling process, and inputting orders. And its main...

- Consumables of Wire Cut MachineOur consumables of wire cut machine mainly include molybdenum wire, idler pulley, soap, electrically conductive block, and water jet board...

- Die Sinker EDMThis die sinker EDM, sometimes also referred to as die sinking EDM, is capable of sector, multihole, and vector process. Designed with the...

- Hole Drilling EDMThis hole drilling EDM is mainly used to process small holes of superhard steel materials, hard alloy, copper, aluminum, and many other electrically...

Lanteky mechatronics was established in 2003, which specializes in processing, manufacturing and selling of electro-hydraulic servo valve and CNC EDM machine. The main products include hydraulic products, such as electro-hydraulic servo valve, servo amplifier, quantitative grease valve, electric cylinder and hydraulic system, and electro machining products, such as electric discharge machine, FANUC wire electric discharge machine and YGS series small hole drilling EDM.

Research Force

1. We are the pioneer of electro-hydraulic servo valve and CNC machine, in more than 50 years, the research results and application level are leading in China. Its modern manufacturing equipment and inspection conditions as well as perfect quality management system have ensured the steady and reliable quality of her products.

2. We own a professional and complete R&D team with rich practical experiences, who can provide standard serious of servo valve, CNC machine, also undertake research of the nonstandard CNC machine, electro-hydraulic servo valve, proportional valve and electro-hydraulic servo system, and offer technology consulting of electro-hydraulic servo system.

3.The company worked repeatedly with industrial enterprise, military enterprises, scientific research institutions, university to research special machine like ceramic die casting machine, valve test bedstand, sensor test bed, vehicle steering system test bed, hydraulic servo system of mobile machinery, and meet different clients' needs.

Service

1. Pre-sale service

(1) There are free samples & pictures to provide except prototype. (both for servo valve and EDM machine)

2. On-purchase service

Generally, the delivery cycle will be about 30 days. The customized product and excessive product will be resolved by mutual agreement. (both for servo valve and EDM machine)

3. After-sales service

The product enjoy 1 year warranty, including the exchange of EDM machine standby board and the repair of servo valve.