Submersed Type Wire EDM

Electric Discharge Machine (EDM)

Electric Discharge Machine (EDM)

Electrical discharge machine works by using the erosion caused by the impulse discharge between the electrode and the conductive material, which has been used in the production of dies....

Amplifier

Amplifier

The amplifier is the servo drive for driving and controlling servo valves and proportional valves. It can realize high accuracy control of all kinds of valves. Servo power amplifier can be composed with other hydraulic systems and measuring transducers into an...

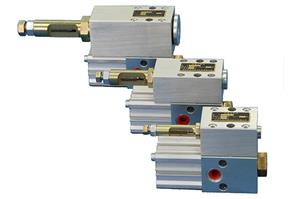

Electro-hydraulic Servo Valve

Electro-hydraulic Servo Valve

Electro hydraulic servo valve can measure the hydraulic oil according to input signal, then to control position, speed, pressure or force in the electro hydraulic systems (generally the pistons and plungers)....

Electro-hydraulic Proportional Valve

Electro-hydraulic Proportional Valve

Electro hydraulic proportional valve is a hydraulic component, which can translate electrical signal to displacement signal by an analog electric-machinery converter. When this valve acts, the electric-machinery converter will response the input signal to move...

Grease Injection Valve

Grease Injection Valve

Grease injection valve is an equipment that can output high pressure medium quantitatively. It is the most important part of the quantitative filling machine, which can fill many different kinds of high viscosity oil such as lithium grease, calcium soap grease...

Single Axis CNC EDM Machine

Single Axis CNC EDM Machine

Single axis CNC EDM machine uses a single axis (Z-axis) with auto-feeding control system (including servo feed system and parameters control system), other axes are manual control axis (X-axis and Y-axis)....

Three Axis CNC EDM Machine

Three Axis CNC EDM Machine

With auto-feeding control system (including servo feed system and parameters control system), three axis CNC EDM machine has wonderful performance on automation and control precision. It is widely used in the field of mould production for electronic component...

CNC EDM Blade Grinder

CNC EDM Blade Grinder

CNC EDM grinder is a machine that can produce PCD cutters through grinding. With 4 CNC controlled axes and 2 manual axes, which is used for the complete processing of PCD tipped tools....

The submersed type EDM machine is equipped with an annealing, fully automatic wire threading system with a scrap wire disposal unit. Its unique intelligent servo-control wire-threading technology, together with multi-detectors makes it the world’s fastest and most reliable (threading at wire break point) automatic wire threading system on the market.

Features

1. Up to 50% faster cutting in workpieces over 200mm (8″) in height

2. Submerged cutting from 0″ to 31″ and 31.49″ of Z Axis stroke.

3. Automatic wire threading up to 31″, anneals the wire over the full stroke for reliability at any height

4. The axis are driven by means of closed loop, direct coupled AC servomotors with 8 millionths resolution and controlled by linear glass scale feedback system.

5. The linear guideways’ patented structure reduces up to 90% of friction and vibration producing appareled accuracy of motion.

Specifications of Submersed Type Wire EDM

|

Item

/ Model |

AU-1400iA

Z800 |

|

X

Travel (in.) |

55.11 |

|

Y

Travel (in.) |

31.49 |

|

Z

Travel (in.) |

31.49 |

|

U

Travel (in.) |

5.9 |

|

V

Travel (in.) |

5.9 |

|

Table

Feed Rate |

40.0″ / min. |

|

Max.

Taper Angle |

+/-

45° |

|

Max.

Workpiece (X,Y,Z in.) |

68.5

× 42.5 × 31.29 |

|

Max.

Workpiece Weight (lbs.) |

16,400 |

|

Wire

Diameter (in.) |

0.006 – 0.013 |

|

Wire

Spool Feed Rate |

60 – 787″ / min. |

|

Wire

Tension (grams) |

300 – 2,200 |

|

Start

Hole Dia. Size (in.) |

0.020 |

|

Max.

Wire Spool (lbs.) |

35

(100 optional) |

|

Positioning

Accuracy (in.) |

+/-

0.00012 |

|

Repeatability

(X,Y in.) |

+/-

0.00008 |

|

Total

Power Required |

20.5

KVA |

|

Deionized

Resin Tank |

2

Cubic Ft. Stainless |

|

Tank

Capacity |

915

Gallons |

|

Floor

Space (W×D×H in.) |

201

× 160 × 134 |

|

CNC

Control Screen |

15″ Color Touch |

|

CNC

Control Device |

64-Bit

Windows CE |

|

Weight

(lbs.) |

20,900 |

Submersed Type Wire EDM Machine

Submersed Type Wire Electrical Discharge Machining

Submersed Type Wire Electrical Discharge Machine

Submersed Type Wire EDM Machinery

Two Stage Servo Valve

Two Stage Servo Valve

Two stage servo valve with integrated electronics for high pressure applications:Electric feedback at main stage spool, Higher resolution, lower hysteresis & zero point drift, Suitable for 3-way or 4-way applications, Improved frequency & step response, Maximu...

Two Way Flow Control Valve

Two Way Flow Control Valve

Two way flow control valves are used to provide pressure compensated flow. The valve design compensates temperature variations to a certain extent. The GFG is optionally equipped with a built-in check valve for the return flow....