Two Stage Servo Valve

Electric Discharge Machine (EDM)

Electric Discharge Machine (EDM)

Electrical discharge machine works by using the erosion caused by the impulse discharge between the electrode and the conductive material, which has been used in the production of dies....

Amplifier

Amplifier

The amplifier is the servo drive for driving and controlling servo valves and proportional valves. It can realize high accuracy control of all kinds of valves. Servo power amplifier can be composed with other hydraulic systems and measuring transducers into an...

Electro-hydraulic Servo Valve

Electro-hydraulic Servo Valve

Electro hydraulic servo valve can measure the hydraulic oil according to input signal, then to control position, speed, pressure or force in the electro hydraulic systems (generally the pistons and plungers)....

Electro-hydraulic Proportional Valve

Electro-hydraulic Proportional Valve

Electro hydraulic proportional valve is a hydraulic component, which can translate electrical signal to displacement signal by an analog electric-machinery converter. When this valve acts, the electric-machinery converter will response the input signal to move...

Grease Injection Valve

Grease Injection Valve

Grease injection valve is an equipment that can output high pressure medium quantitatively. It is the most important part of the quantitative filling machine, which can fill many different kinds of high viscosity oil such as lithium grease, calcium soap grease...

Single Axis CNC EDM Machine

Single Axis CNC EDM Machine

Single axis CNC EDM machine uses a single axis (Z-axis) with auto-feeding control system (including servo feed system and parameters control system), other axes are manual control axis (X-axis and Y-axis)....

Three Axis CNC EDM Machine

Three Axis CNC EDM Machine

With auto-feeding control system (including servo feed system and parameters control system), three axis CNC EDM machine has wonderful performance on automation and control precision. It is widely used in the field of mould production for electronic component...

CNC EDM Blade Grinder

CNC EDM Blade Grinder

CNC EDM grinder is a machine that can produce PCD cutters through grinding. With 4 CNC controlled axes and 2 manual axes, which is used for the complete processing of PCD tipped tools....

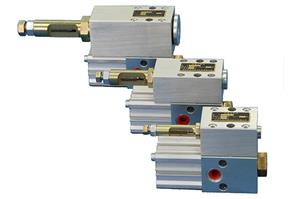

Two stage servo valve with integrated electronics for high pressure applications:Electric feedback at main stage spool, Higher resolution, lower hysteresis & zero point drift, Suitable for 3-way or 4-way applications, Improved frequency & step response, Maximum operating main stage pressure 500 bar, Maximum flow 65 l/min at 70 bar, External pilot supply (5 port).

Features

1. In closed loop systems that require high degrees of resolution i.e. force or pressure control it is essential to equal or better the recommended ISO cleanliness levels.

2. Off-line filtration has been proven to effectively remove particulates across the main ISO classification levels without detriment to fluid composition.

3. There is also a very significant reduction on the dependency of inline filters that can and do fatigue when high transient pressures exist.

4. Additional condition monitoring can provide warnings on a number of elements during service and effective flushing procedures. Please feel free to contact our sales team for further details.

CNC EDM Double Ox-head Mirror Machine

High Pressure Two Stage Servo Valves

Two Stage Servo Control Valve

High Pressure Servo Control Valve

Two Way Flow Control Valve

Two Way Flow Control Valve

Two way flow control valves are used to provide pressure compensated flow. The valve design compensates temperature variations to a certain extent. The GFG is optionally equipped with a built-in check valve for the return flow....

Wire EDM Machine

Wire EDM Machine

Rigid linear motor driven high-performance wire EDM machine is one of the newest additions to the sodick product line-up. This machine includes some exciting new features, such as; SPW (Smart Pulse Wire) control with the Smart Pulse Generator and technologies ...