Multi-axis Servo Amplifier

Electric Discharge Machine (EDM)

Electric Discharge Machine (EDM)

Electrical discharge machine works by using the erosion caused by the impulse discharge between the electrode and the conductive material, which has been used in the production of dies....

Amplifier

Amplifier

The amplifier is the servo drive for driving and controlling servo valves and proportional valves. It can realize high accuracy control of all kinds of valves. Servo power amplifier can be composed with other hydraulic systems and measuring transducers into an...

Electro-hydraulic Servo Valve

Electro-hydraulic Servo Valve

Electro hydraulic servo valve can measure the hydraulic oil according to input signal, then to control position, speed, pressure or force in the electro hydraulic systems (generally the pistons and plungers)....

Electro-hydraulic Proportional Valve

Electro-hydraulic Proportional Valve

Electro hydraulic proportional valve is a hydraulic component, which can translate electrical signal to displacement signal by an analog electric-machinery converter. When this valve acts, the electric-machinery converter will response the input signal to move...

Grease Injection Valve

Grease Injection Valve

Grease injection valve is an equipment that can output high pressure medium quantitatively. It is the most important part of the quantitative filling machine, which can fill many different kinds of high viscosity oil such as lithium grease, calcium soap grease...

Single Axis CNC EDM Machine

Single Axis CNC EDM Machine

Single axis CNC EDM machine uses a single axis (Z-axis) with auto-feeding control system (including servo feed system and parameters control system), other axes are manual control axis (X-axis and Y-axis)....

Three Axis CNC EDM Machine

Three Axis CNC EDM Machine

With auto-feeding control system (including servo feed system and parameters control system), three axis CNC EDM machine has wonderful performance on automation and control precision. It is widely used in the field of mould production for electronic component...

CNC EDM Blade Grinder

CNC EDM Blade Grinder

CNC EDM grinder is a machine that can produce PCD cutters through grinding. With 4 CNC controlled axes and 2 manual axes, which is used for the complete processing of PCD tipped tools....

Multi-axis servo amplifier from the DIAS Drive 1000 series can control up to 6 motors. In addition to the housing, the drive regulators also share the controller, intermediate circuit and heat sink.

Not only can the construction volume be reduced and the stability increased, the equipment costs are also lowered. The 6-axis device measures only 21 cm in width, 59 cm in height and has an installation depth of 22 cm. In the new compact drive series, there are variants with three and four axes, which allow that the number of axes are precisely tailored to the application. Per axis, between 5 and 20 A rated current and 10 to 40 A peak current are possible.

External plug-in feedback modules provide flexibility. The machine manufacturer can therefore customize the encoder systems to the respective application. Currently, Resolver, EnDat 2.1 and Hiperface DSL modules are available.

For the SDD 1000 series, the motor control algorithm was further developed. Whereby, precision and dynamics could be further increased. Controller cycle times of only 62.5 µs provide highly exact positioning at a higher speed. The internal intermediate circuit system ensures efficient energy use and distribution.

Multi-axis Servo Drive

Multi-axis Servo Controller

Multi-axis Servo Amplifier for Motor

Multi-axis AC servo-amplifier

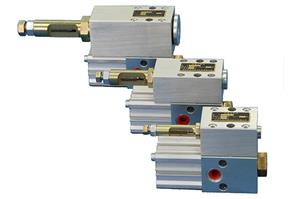

Pilot Operated Proportional Directional Control Valve

Pilot Operated Proportional Directional Control Valve

The pilot operated proportional directional control valve works with barometric feedback of the main stage to the pressure reducing pilot valve. The pilot control pressure of 25 bar allows high flow rates at maximum stability....

Pilot-Operated Servo Valve

Pilot-Operated Servo Valve

Pilot operated servo valve with built-in fieldbus interfaces enable operating parameters to be set, activate the valve and monitor its performance. Different fail-safe options available allow the best fit to the application....