EDM Machine

Electric Discharge Machine (EDM)

Electric Discharge Machine (EDM)

Electrical discharge machine works by using the erosion caused by the impulse discharge between the electrode and the conductive material, which has been used in the production of dies....

Amplifier

Amplifier

The amplifier is the servo drive for driving and controlling servo valves and proportional valves. It can realize high accuracy control of all kinds of valves. Servo power amplifier can be composed with other hydraulic systems and measuring transducers into an...

Electro-hydraulic Servo Valve

Electro-hydraulic Servo Valve

Electro hydraulic servo valve can measure the hydraulic oil according to input signal, then to control position, speed, pressure or force in the electro hydraulic systems (generally the pistons and plungers)....

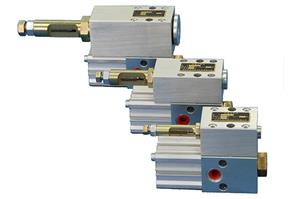

Electro-hydraulic Proportional Valve

Electro-hydraulic Proportional Valve

Electro hydraulic proportional valve is a hydraulic component, which can translate electrical signal to displacement signal by an analog electric-machinery converter. When this valve acts, the electric-machinery converter will response the input signal to move...

Grease Injection Valve

Grease Injection Valve

Grease injection valve is an equipment that can output high pressure medium quantitatively. It is the most important part of the quantitative filling machine, which can fill many different kinds of high viscosity oil such as lithium grease, calcium soap grease...

Single Axis CNC EDM Machine

Single Axis CNC EDM Machine

Single axis CNC EDM machine uses a single axis (Z-axis) with auto-feeding control system (including servo feed system and parameters control system), other axes are manual control axis (X-axis and Y-axis)....

Three Axis CNC EDM Machine

Three Axis CNC EDM Machine

With auto-feeding control system (including servo feed system and parameters control system), three axis CNC EDM machine has wonderful performance on automation and control precision. It is widely used in the field of mould production for electronic component...

CNC EDM Blade Grinder

CNC EDM Blade Grinder

CNC EDM grinder is a machine that can produce PCD cutters through grinding. With 4 CNC controlled axes and 2 manual axes, which is used for the complete processing of PCD tipped tools....

EDM Machine uses an electrode to create electrical discharges to remove metal and make cuts. As the electrical charge passes between the electrode and the metal being machined, cuts are made into the metal. A continuously flowing fluid is used to flush these pieces of material away.

Electrical Discharge Machining Types

1. Wire Electrical Discharge Machining

The wire EDM process uses a thin metal wire fed from a spool through the workpiece to cut plates, make punches, tool and dies. In wire electrical discharge machining, the metal and wire cutter are submerged water, which acts as an electrical insulator.

2. Small Hole EDM Machine

Small hole EDM is used to drill rows of holes into the leading and trailing edges of turbine blades used in jet engines. Gas flow through these small holes allows the engines to use higher temperatures than otherwise possible.

3. Sinker Electrical Discharge Machining

In the sinker EDM process, an electrode and the metal are submerged in an insulated liquid, in this case it’s usually oil, and a power supply generates an electrical charge between the electrode and the metal. A spark occurs that cuts the metal. In sinker electrical discharge machining, several hundred thousand sparks occur per second.

Sinker Electrical Discharge Machining

Sinker EDM Machine

Sinker EDM Machinery

Small Hole EDM Machine

Electric proportional valves (EPC) are electromagnetically-actuated, proportional control valves designed for use in closed loop flow or pressure control systems. When coupled with a flow sensor or pressure transducer and a proportional electronic controller, ...

Electrohydraulic Valve

Electrohydraulic Valve

High-performance electrohydraulic valves are usually classified as either servo or proportional, a distinction that gives an indication of expected performance. Unfortunately, this classification tends to generalize and blur the true differences between variou...