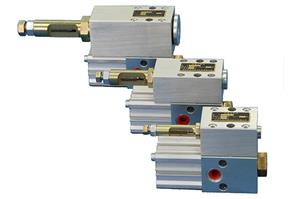

Electrohydraulic Valve

Electric Discharge Machine (EDM)

Electric Discharge Machine (EDM)

Electrical discharge machine works by using the erosion caused by the impulse discharge between the electrode and the conductive material, which has been used in the production of dies....

Amplifier

Amplifier

The amplifier is the servo drive for driving and controlling servo valves and proportional valves. It can realize high accuracy control of all kinds of valves. Servo power amplifier can be composed with other hydraulic systems and measuring transducers into an...

Electro-hydraulic Servo Valve

Electro-hydraulic Servo Valve

Electro hydraulic servo valve can measure the hydraulic oil according to input signal, then to control position, speed, pressure or force in the electro hydraulic systems (generally the pistons and plungers)....

Electro-hydraulic Proportional Valve

Electro-hydraulic Proportional Valve

Electro hydraulic proportional valve is a hydraulic component, which can translate electrical signal to displacement signal by an analog electric-machinery converter. When this valve acts, the electric-machinery converter will response the input signal to move...

Grease Injection Valve

Grease Injection Valve

Grease injection valve is an equipment that can output high pressure medium quantitatively. It is the most important part of the quantitative filling machine, which can fill many different kinds of high viscosity oil such as lithium grease, calcium soap grease...

Single Axis CNC EDM Machine

Single Axis CNC EDM Machine

Single axis CNC EDM machine uses a single axis (Z-axis) with auto-feeding control system (including servo feed system and parameters control system), other axes are manual control axis (X-axis and Y-axis)....

Three Axis CNC EDM Machine

Three Axis CNC EDM Machine

With auto-feeding control system (including servo feed system and parameters control system), three axis CNC EDM machine has wonderful performance on automation and control precision. It is widely used in the field of mould production for electronic component...

CNC EDM Blade Grinder

CNC EDM Blade Grinder

CNC EDM grinder is a machine that can produce PCD cutters through grinding. With 4 CNC controlled axes and 2 manual axes, which is used for the complete processing of PCD tipped tools....

High-performance electrohydraulic valves are usually classified as either servo or proportional, a distinction that gives an indication of expected performance. Unfortunately, this classification tends to generalize and blur the true differences between various valve styles. Selection depends on the application, and each valve has merit when it comes to controlling pressure or flow.

Features of Electrohydraulic Valve

1. Traditionally, the term servovalve describes valves that use closed-loop control. They monitor and feed back the main-stage spool position to a pilot stage or driver either mechanically or electronically.

2. Proportional valves, on the other hand, move the main-stage spool in direct proportion to a command signal, but they usually do not have any means of automatic error correction (feedback) within the valve.

3. The electromagnetic circuit of a nozzle flapper or jet-pipe torque motor is essentially the same. The differences between the two lie in the hydraulic bridge design.

4. A hydraulic bridge controls the pilot flow which, in turn, controls the main-stage spool movement. In a nozzle flapper, the torque produced on the armature by the magnetic field moves the flapper toward either nozzle depending on command-signal polarity.

Slip-in Cartridge Valve

Two Stage Servo Valves

Electro Hydraulic Valves

Two Stage Electro Hydraulic Valve

Flow control valves are a type of flow valve. They generate a set constant flow rate, largely independently of the load.The flow control valve type SD, SF and SK can be freely adjusted with different mechanical actuations. The flow control valve type SD, SF an...

The flushing type wire EDM machines are equipped with an annealing, fully automatic wire threading system (AWT) with a scrap wire disposal unit. This controls conversational cutting condition selection, on board operation manuals and help menus along with a lo...