CNC Die Sinking EDM

Electric Discharge Machine (EDM)

Electric Discharge Machine (EDM)

Electrical discharge machine works by using the erosion caused by the impulse discharge between the electrode and the conductive material, which has been used in the production of dies....

Amplifier

Amplifier

The amplifier is the servo drive for driving and controlling servo valves and proportional valves. It can realize high accuracy control of all kinds of valves. Servo power amplifier can be composed with other hydraulic systems and measuring transducers into an...

Electro-hydraulic Servo Valve

Electro-hydraulic Servo Valve

Electro hydraulic servo valve can measure the hydraulic oil according to input signal, then to control position, speed, pressure or force in the electro hydraulic systems (generally the pistons and plungers)....

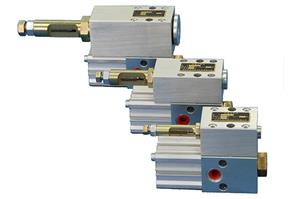

Electro-hydraulic Proportional Valve

Electro-hydraulic Proportional Valve

Electro hydraulic proportional valve is a hydraulic component, which can translate electrical signal to displacement signal by an analog electric-machinery converter. When this valve acts, the electric-machinery converter will response the input signal to move...

Grease Injection Valve

Grease Injection Valve

Grease injection valve is an equipment that can output high pressure medium quantitatively. It is the most important part of the quantitative filling machine, which can fill many different kinds of high viscosity oil such as lithium grease, calcium soap grease...

Single Axis CNC EDM Machine

Single Axis CNC EDM Machine

Single axis CNC EDM machine uses a single axis (Z-axis) with auto-feeding control system (including servo feed system and parameters control system), other axes are manual control axis (X-axis and Y-axis)....

Three Axis CNC EDM Machine

Three Axis CNC EDM Machine

With auto-feeding control system (including servo feed system and parameters control system), three axis CNC EDM machine has wonderful performance on automation and control precision. It is widely used in the field of mould production for electronic component...

CNC EDM Blade Grinder

CNC EDM Blade Grinder

CNC EDM grinder is a machine that can produce PCD cutters through grinding. With 4 CNC controlled axes and 2 manual axes, which is used for the complete processing of PCD tipped tools....

With a full complement of available options, the CNC die sinking EDM has the right equipment for every application. The fully functional C Axis can be fit with any commercial chuck for electrode holding compatibility and can hold up to 50 pounds. Shuttle and rotary automatic electrode changers or standalone FANUC robot can be installed to accommodate untended operations from roughing to finishing changing electrodes and work pieces.

Features

1. Machining modes include 1, 2 and 3 axis linear, 2 axis contouring and Helical

2. Dual Digital synchronized pulse generator for best speed, surface and wear

3. Intelligent automatic DC arc protection and parameter optimization

4. Optional C Axis with rotation, indexing and helical machining

5. Optional 4 to 16 position shuttle or rotary automatic electrode changer (AEC)

6. Optional FANUC robot interface for automatic electrode (AEC) or Work (AWC) changing

7. Hardened precision work table with standard T Slots

8. Auto Fire Extinguisher with fire and fluid level sensors

9. 24 fully selectable, configurable 2D and 3D orbit patterns

Specifications of CNC Die Sinking EDM

| Item / Model | DS-430S-CMAX | DS-550-CMAX | DS-645-CMAX | DS-1270-CMAX | DS-1470-CMAX | DS-1510-CMAX |

| X-Axis | 16″ | 20″ | 24″ | 47″ | 55″ | 59″ |

| Y-Axis | 12″ | 16″ | 18″ | 28″ | 28″ | 39″ |

| Z-Axis (servo) | 12″ | 14″ | 16″ | 20″ | 20″ | 24″ |

| Table Size | 26” × 14” | 32” × 18” | 40″ × 24″ | 53” × 32” | 67” × 37” | 62” × 43” |

| Max. Workpiece Size | 38” × 22” × 14” | 38”× 22”× 14” | 59” × 37” × 22” | 83” × 49” × 24” | 87” × 52” × 24” | 90” × 67” x 32” |

| Max. Workpiece Weight | 1,210 lbs. | 2,970 lbs | 6,600 lbs. | 11,000 lbs. | 13,200 lbs. | 24,200lbs |

| Max. Electrode Weigh | Platen -264 lbs | Platen -484 lbs. | Platen -550 lbs. | Platen -880 lbs. | Platen -990 lbs. | Platen-1,100 lbs. |

| Distance from RAM to Table | 11” - 22” | 11” - 26” | 12” - 28” | 20” - 40” | 22” - 41” | 53” - 29” |

| Machine Dimensions | 94” × 71” × 93” | 153” × 71” × 96” | 109” × 114” × 101” | 146” × 141” × 128” | 157” × 157” ×128” | 157” × 157” x 143” |

| Machine Weight | 2,640 lbs. | 4,300 lbs. | 8,580 lbs. | 14,300 lbs. | 17,600 lbs. | 29,700 lbs. |

| Tank Capacity | 100 gal. | 145 gal. | 320 gal. | 545 gal. | 602 gal. | 694 gal. |

CNC Die Sinking EDM Machine

CNC Die Sinking Electrical Discharge Machining

CNC Die Sinking EDM Machinery

CNC Die Sinking Electrical Discharge Machine

CNC EDM Double Ox-head Mirror Machine

CNC EDM Double Ox-head Mirror Machine

CNC EDM double ox-head mirror machine is equipped with automatic alarm security device that assures operation safety. It consists of CNC system, touch screen input, manual control box, etc. Mirror finishing & special circuit is for finishing hard alloy....

CNC Grinder

CNC Grinder

The biggest advantage of a machine like the G5 CNC grinder is its ability to eliminate non-value-added time in the manufacturing process. Because you can go from milling to grinding in one machine, you’re not only saving on capital equipment, but you’re also a...