CNC Grinder

Electric Discharge Machine (EDM)

Electric Discharge Machine (EDM)

Electrical discharge machine works by using the erosion caused by the impulse discharge between the electrode and the conductive material, which has been used in the production of dies....

Amplifier

Amplifier

The amplifier is the servo drive for driving and controlling servo valves and proportional valves. It can realize high accuracy control of all kinds of valves. Servo power amplifier can be composed with other hydraulic systems and measuring transducers into an...

Electro-hydraulic Servo Valve

Electro-hydraulic Servo Valve

Electro hydraulic servo valve can measure the hydraulic oil according to input signal, then to control position, speed, pressure or force in the electro hydraulic systems (generally the pistons and plungers)....

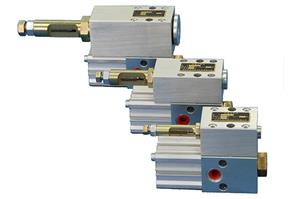

Electro-hydraulic Proportional Valve

Electro-hydraulic Proportional Valve

Electro hydraulic proportional valve is a hydraulic component, which can translate electrical signal to displacement signal by an analog electric-machinery converter. When this valve acts, the electric-machinery converter will response the input signal to move...

Grease Injection Valve

Grease Injection Valve

Grease injection valve is an equipment that can output high pressure medium quantitatively. It is the most important part of the quantitative filling machine, which can fill many different kinds of high viscosity oil such as lithium grease, calcium soap grease...

Single Axis CNC EDM Machine

Single Axis CNC EDM Machine

Single axis CNC EDM machine uses a single axis (Z-axis) with auto-feeding control system (including servo feed system and parameters control system), other axes are manual control axis (X-axis and Y-axis)....

Three Axis CNC EDM Machine

Three Axis CNC EDM Machine

With auto-feeding control system (including servo feed system and parameters control system), three axis CNC EDM machine has wonderful performance on automation and control precision. It is widely used in the field of mould production for electronic component...

CNC EDM Blade Grinder

CNC EDM Blade Grinder

CNC EDM grinder is a machine that can produce PCD cutters through grinding. With 4 CNC controlled axes and 2 manual axes, which is used for the complete processing of PCD tipped tools....

The biggest advantage of a machine like the G5 CNC grinder is its ability to eliminate non-value-added time in the manufacturing process. Because you can go from milling to grinding in one machine, you’re not only saving on capital equipment, but you’re also able to perform several operations in a single setup, eliminating all of the out-of-cut time that does nothing but add to your costs and lead-time.

Specification of CNC Grinder

| Pallet | 9.8" |

| X | 20.5" |

| Y | 22.0" |

| Z | 23.6" |

| Aaxis | None |

| Baxis | 270° (-90°to +180°) |

| Caxis | 360° |

| Spindle RPM | 12,000 rpm |

| Rapid Traverse | 1,890 ipm |

| Cutting Feedrate | 1,890 ipm |

| Maximum Workpiece | 17.3 Ø × 15 SR |

| Maximum Payload | 265 lbs |

| ATC Capacity | 60 tools |

| Maximum Tool Length (Cat) | 14.2" |

| Maximum Tool Length (HSK) | 15.7" |

| Maximum Tool Diameter | 2.8"/ 8.7" with limitation |

| Maximum Tool Weight | 26 lbs |

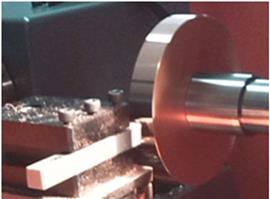

CNC Grinding Machine for Grinding Turbine Parts

5-axis Horizontal CNC Grinder

5-axis Horizontal CNC Grinding Machine

CNC Grinding Machinery

CNC Grinding

CNC Grinding

Tight tolerances and surface finishes are everyday work for us. Our grinding department specializes in carbide and ceramic CNC grinding. Whether it's just grinding you're looking for, or a complete part, we can do it for you....

CNC Grinding Equipment

CNC Grinding Equipment

Our Grinding Equipment includes a continuous dress creep feed that operates up to 100 HP with a 20" wheel, 4-axis continuous dress creep feed, 5-axis CBN, 1 & 2 spindle cylindrical verticals, and CNC surface grinders....