Wire EDM

Electric Discharge Machine (EDM)

Electric Discharge Machine (EDM)

Electrical discharge machine works by using the erosion caused by the impulse discharge between the electrode and the conductive material, which has been used in the production of dies....

Amplifier

Amplifier

The amplifier is the servo drive for driving and controlling servo valves and proportional valves. It can realize high accuracy control of all kinds of valves. Servo power amplifier can be composed with other hydraulic systems and measuring transducers into an...

Electro-hydraulic Servo Valve

Electro-hydraulic Servo Valve

Electro hydraulic servo valve can measure the hydraulic oil according to input signal, then to control position, speed, pressure or force in the electro hydraulic systems (generally the pistons and plungers)....

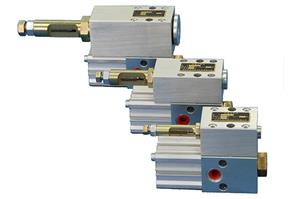

Electro-hydraulic Proportional Valve

Electro-hydraulic Proportional Valve

Electro hydraulic proportional valve is a hydraulic component, which can translate electrical signal to displacement signal by an analog electric-machinery converter. When this valve acts, the electric-machinery converter will response the input signal to move...

Grease Injection Valve

Grease Injection Valve

Grease injection valve is an equipment that can output high pressure medium quantitatively. It is the most important part of the quantitative filling machine, which can fill many different kinds of high viscosity oil such as lithium grease, calcium soap grease...

Single Axis CNC EDM Machine

Single Axis CNC EDM Machine

Single axis CNC EDM machine uses a single axis (Z-axis) with auto-feeding control system (including servo feed system and parameters control system), other axes are manual control axis (X-axis and Y-axis)....

Three Axis CNC EDM Machine

Three Axis CNC EDM Machine

With auto-feeding control system (including servo feed system and parameters control system), three axis CNC EDM machine has wonderful performance on automation and control precision. It is widely used in the field of mould production for electronic component...

CNC EDM Blade Grinder

CNC EDM Blade Grinder

CNC EDM grinder is a machine that can produce PCD cutters through grinding. With 4 CNC controlled axes and 2 manual axes, which is used for the complete processing of PCD tipped tools....

Wire EDM is equipped with SD Master, which ensures machining repeat ability hole-to-hole and machine-to-machine. Cutting Efficiency is 20% better than any of our competition, and up to 50% in tall workpieces-capacity is efficiency.

Features

1. Faster cutting in variable condition applications – especially great for die/mold applications

2. Intelligent Corner/Arc Control for high precision on any shape

3. Unique Patented Design on the industry’s most reliable Automatic Wire Threader – increases thou-put

4. Rotary Table can be positioned for both vertical and horizontal applications

Specifications of Wire EDM

|

Item

/ Model |

GE-43SA |

|

X

Travel (in.) |

15.75 |

|

Y

Travel (in.) |

11.81 |

|

Z

Travel (in.) |

8.66 |

|

U

Travel (in.) |

2.36 |

|

V

Travel (in.) |

2.36 |

|

Table

Feed Rates |

40″

/ min. |

|

Max

. Taper Angle |

+/-

45° |

|

Max

. Workpiece ( X ,Y,Z in.) |

29.52 × 23.62 × 8.46 |

|

Max

. Workpiece Weight (lbs.) |

1,067 |

|

Wire

Diameter (in.) |

0.006

– 0.013 |

|

Wire

Spool Feed Rate |

60

– 787 ” / min. |

|

Wire

Tension (grams) |

300

– 2,200 |

|

Start

Hole Dia. Size (in.) |

0.020 |

|

Max

. Wire Spool (lbs.) |

22 |

|

Positioning

Accuracy (in.) |

+/-

0.00012 |

|

Repeatability

(X ,Y in.) |

+/-

0.00008 |

|

Total

Power Required |

20.5

KVA |

|

Deionized

Resin Tank |

1

Cubic Ft. Stainless |

|

Tank

Capacity |

220

Gallons |

|

Floor

Space (W×D × H in.) |

94 × 108 × 78 |

|

CNC

Control Screen |

15″

Color Monitor |

|

CNC

Control Device |

64-Bit

Windows CE Based PC |

|

Weight

(lbs.) |

5,830 |

Wire EDM Machinery

Wire EDM Equipment

Wire Electrical Discharge Machining

Wire EDM Electrical Discharge Machinery

Three Axis EDM Machine

Three Axis EDM Machine

This three axis EDM machine includes SD Master for stabilized power discharge while cutting and Auto Wire Threading (hands-down the best in the market). Standard accessories include: Upper/Lower Flushing Nozzles, Chiller Unit, Ion Resin Tank, Conductor Plates...

AC Servo Drive

AC Servo Drive

The AC servo drive is a modular and very compact servo drive system that has optimized power loss and was especially designed for use in multi-axial applications. It can cater up to eight servo axes per system. There are two different power modules that can be...