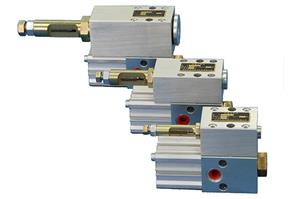

Pressure and Flow Control Valve

Electric Discharge Machine (EDM)

Electric Discharge Machine (EDM)

Electrical discharge machine works by using the erosion caused by the impulse discharge between the electrode and the conductive material, which has been used in the production of dies....

Amplifier

Amplifier

The amplifier is the servo drive for driving and controlling servo valves and proportional valves. It can realize high accuracy control of all kinds of valves. Servo power amplifier can be composed with other hydraulic systems and measuring transducers into an...

Electro-hydraulic Servo Valve

Electro-hydraulic Servo Valve

Electro hydraulic servo valve can measure the hydraulic oil according to input signal, then to control position, speed, pressure or force in the electro hydraulic systems (generally the pistons and plungers)....

Electro-hydraulic Proportional Valve

Electro-hydraulic Proportional Valve

Electro hydraulic proportional valve is a hydraulic component, which can translate electrical signal to displacement signal by an analog electric-machinery converter. When this valve acts, the electric-machinery converter will response the input signal to move...

Grease Injection Valve

Grease Injection Valve

Grease injection valve is an equipment that can output high pressure medium quantitatively. It is the most important part of the quantitative filling machine, which can fill many different kinds of high viscosity oil such as lithium grease, calcium soap grease...

Single Axis CNC EDM Machine

Single Axis CNC EDM Machine

Single axis CNC EDM machine uses a single axis (Z-axis) with auto-feeding control system (including servo feed system and parameters control system), other axes are manual control axis (X-axis and Y-axis)....

Three Axis CNC EDM Machine

Three Axis CNC EDM Machine

With auto-feeding control system (including servo feed system and parameters control system), three axis CNC EDM machine has wonderful performance on automation and control precision. It is widely used in the field of mould production for electronic component...

CNC EDM Blade Grinder

CNC EDM Blade Grinder

CNC EDM grinder is a machine that can produce PCD cutters through grinding. With 4 CNC controlled axes and 2 manual axes, which is used for the complete processing of PCD tipped tools....

Pressure and flow control valve is directly driven by linear force motor: No pilot flow required. Linear force motor with high force range (improves operating limits): No flow limitations.

Features

1. Directly driven design: Pressure-independent dynamic performance

2. Low current consumption at and near hydraulic null

3. Spool is in spring-centered position at loss of power supply: Actuator stops

4. Integrated digital electronics with integrated pressure transducer allows a high grade of flexibility

Parameters of Pressure and Flow Control Valve

|

Hydraulic

Data |

|

|

Rated

Flow |

5

to 100 l/min (1.3 to 26.3 gpm) @ ∆p 35 bar (500 psi) per land |

|

Maximum

Flow |

180

l/min (47 gpm) size 05 |

|

Maximum

Operating Pressure |

350

bar (5,000 psi) |

|

Mounting

Pattern |

ISO

4401 Size 03 and 05 (NG 6 and 10) |

|

100%

Step Response |

8

ms @ 210 bar (3,000 psi) |

|

Electrical

Data |

|

|

Supply

Voltage |

24

VDC (18 to 32 VDC) |

|

Rated

Signal Options |

+/-10

V, +/-10 mA and 4-20 mA |

|

Options |

Fieldbus

Interface |

Pilot-Operated Servo Valve

Direct Operated Pressure and Flow Control Valve

Pressure and Flow Control Servo Valve

Pressure and Flow Control Valve for Analog Signals

Programmable Servo Drive

Programmable Servo Drive

Programmable servo drives offer approved safety functions per EN 61800-5-2 and Safety PLC functions. Configuration, programming and validation is performed with the Moog Servo Drive Software with Safety PLC Functions. This is a module of both the Programmable ...

Programmable Single Axis Servo Drive

Programmable Single Axis Servo Drive

Programmable single axis servo drives for the control of sychronous and asynchronous machines, delivering the highest level of dynamic response, smooth performance and application versatility. It is a module of the programmable multi axis servo drive system....