Die Sinking Electrical Discharge Machine

Electric Discharge Machine (EDM)

Electric Discharge Machine (EDM)

Electrical discharge machine works by using the erosion caused by the impulse discharge between the electrode and the conductive material, which has been used in the production of dies....

Amplifier

Amplifier

The amplifier is the servo drive for driving and controlling servo valves and proportional valves. It can realize high accuracy control of all kinds of valves. Servo power amplifier can be composed with other hydraulic systems and measuring transducers into an...

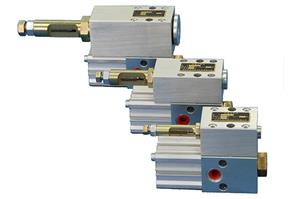

Electro-hydraulic Servo Valve

Electro-hydraulic Servo Valve

Electro hydraulic servo valve can measure the hydraulic oil according to input signal, then to control position, speed, pressure or force in the electro hydraulic systems (generally the pistons and plungers)....

Electro-hydraulic Proportional Valve

Electro-hydraulic Proportional Valve

Electro hydraulic proportional valve is a hydraulic component, which can translate electrical signal to displacement signal by an analog electric-machinery converter. When this valve acts, the electric-machinery converter will response the input signal to move...

Grease Injection Valve

Grease Injection Valve

Grease injection valve is an equipment that can output high pressure medium quantitatively. It is the most important part of the quantitative filling machine, which can fill many different kinds of high viscosity oil such as lithium grease, calcium soap grease...

Single Axis CNC EDM Machine

Single Axis CNC EDM Machine

Single axis CNC EDM machine uses a single axis (Z-axis) with auto-feeding control system (including servo feed system and parameters control system), other axes are manual control axis (X-axis and Y-axis)....

Three Axis CNC EDM Machine

Three Axis CNC EDM Machine

With auto-feeding control system (including servo feed system and parameters control system), three axis CNC EDM machine has wonderful performance on automation and control precision. It is widely used in the field of mould production for electronic component...

CNC EDM Blade Grinder

CNC EDM Blade Grinder

CNC EDM grinder is a machine that can produce PCD cutters through grinding. With 4 CNC controlled axes and 2 manual axes, which is used for the complete processing of PCD tipped tools....

The die sinking electrical discharge machine is the latest entree to the successful EDM lineup and was introduced at this year's EMO. This revamped machine has the ability to drill holes in blades and vanes at a speed four times faster than current technologies while making fan shaped machining available in the same step. Other notable features include a patented combined guide and electrode holder, which allows the device to deliver super fast electrode changes and a revolutionary detection technology to avoid damage in the workplace.

1. The EDBV3 is a larger version of its sibling and was launched at the EDM last year.

2. The Makino EDBV3 sinker EDM (SEDM) brings to the table bigger strokes (XYZ 800 x 600 x 500 mm) in combination with all new drilling technology to enable cooling holes in vanes and turbine blades to be machined at 1 mm/sec or four times faster than traditional EDM technology.

3. Substantial productivity gains are also achieved thanks to the contouring program, which enables fan shaped machining to be completed in the same step as drilling.

Die Sinking EDM Machine

Multi-axis Servo Amplifier

Die Sinking Electrical Discharge Machining

Die Sinking EDM Machinery

Digital control servo valve leads the way in high performance closed-loop hydraulic valves used in the world’s most demanding environments and applications. It provide the ability to tailor the valves and tune the software to meet your exact machine requiremen...

Directional spool valves are a type of directional valve. They control the direction of movement and the velocity of single and double-acting hydraulic consumers. The directional spool valve type SWP is available as a manifold mounting valve. Type SW is availa...